Disintegration and prevention of grease stratification in pumping sumps (wet wells) and tanks

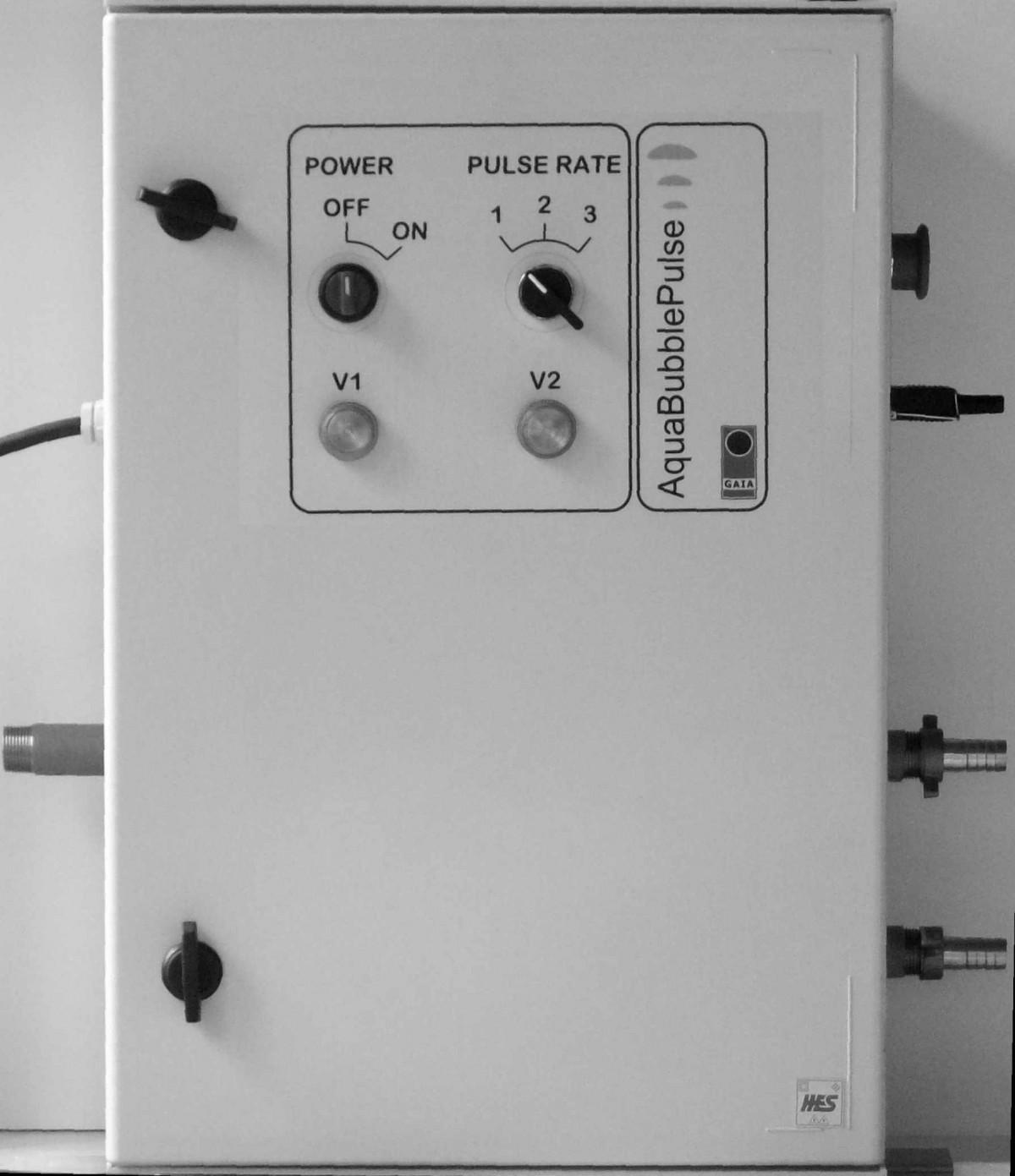

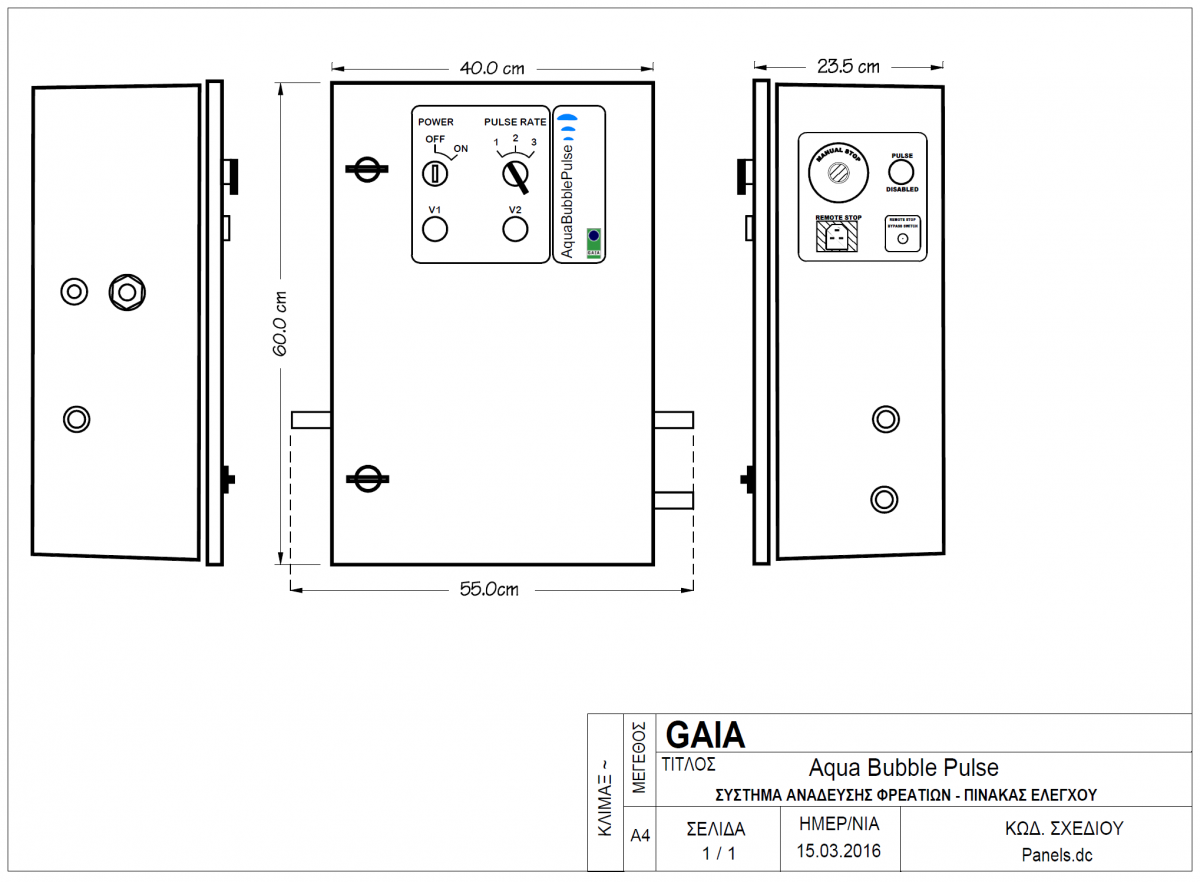

The AquaBubblePulse® system is an innovative tank and shaft stirring system through compressed air pulses.

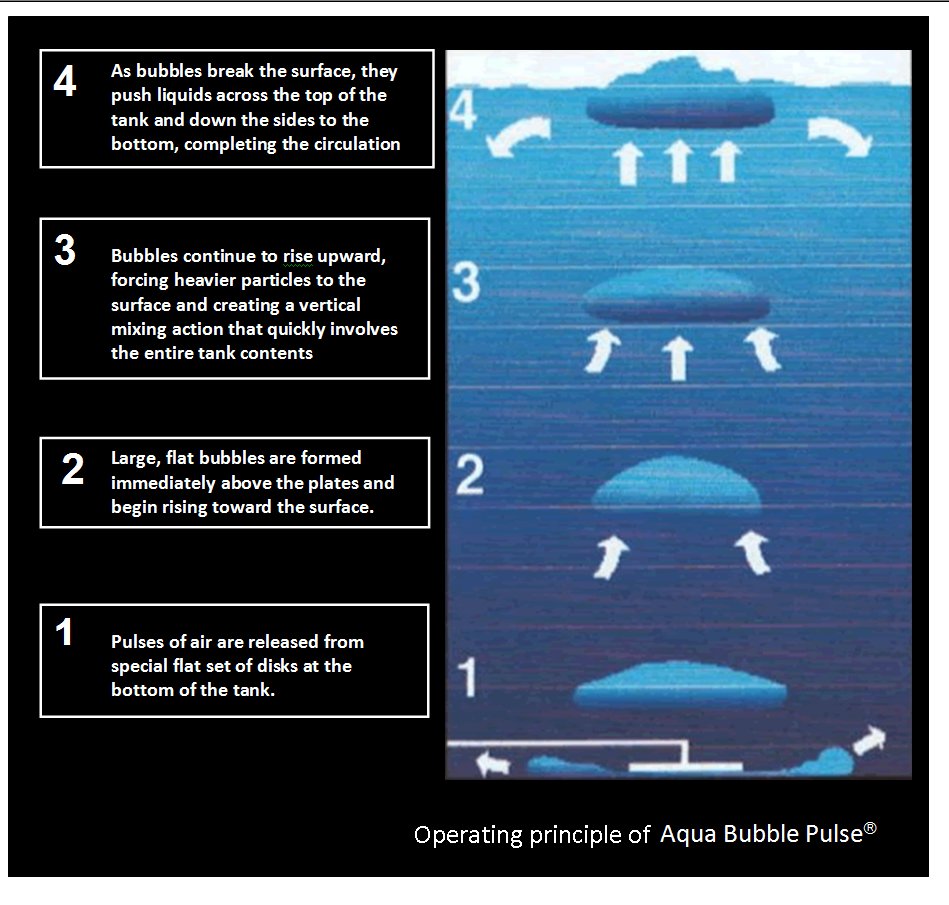

The AquaBubblePulse® injects compressed air pulses into one or more special stainless steel discs placed at the bottom to create large single bubbles that mix in a short time and with low power consumption, all the contents of the tank.

The large air bubbles formed after each air pulse push the overlying liquid mass upwards creating a vertical motion that forces the contents of the tank to move towards its walls.

In this way, a circular stirring motion is started, which achieves the rapid and uniform mixing of the entire contents of the tank.

In the case of a wet well where a layer of grease has formed, its continuous stirring achieves its decomposition and prevents its re-formation.

AquaBubblePulse® can be applied to any shape or size of tank or wet well regardless of its content level. Stirring can even start with a level of a few tens of centimeters of liquid in the tank.

AquaBubblePulse® has no moving parts in the tank, which means that maintenance requirements are very low. The only moving parts are the contents of the tank.

In particular, the use of AquaBubblePulse® ® in sewage wet wells and pumping sumps offers significant benefits:

- Minimizes the potential for pump failure due to intake of large chunks of grease

- Prevents the malfunction of the “float switches” – with the unpleasant consequences of overflow

- Significantly reduces the emission of unpleasant odors

- It has low operating costs due to low power consumption